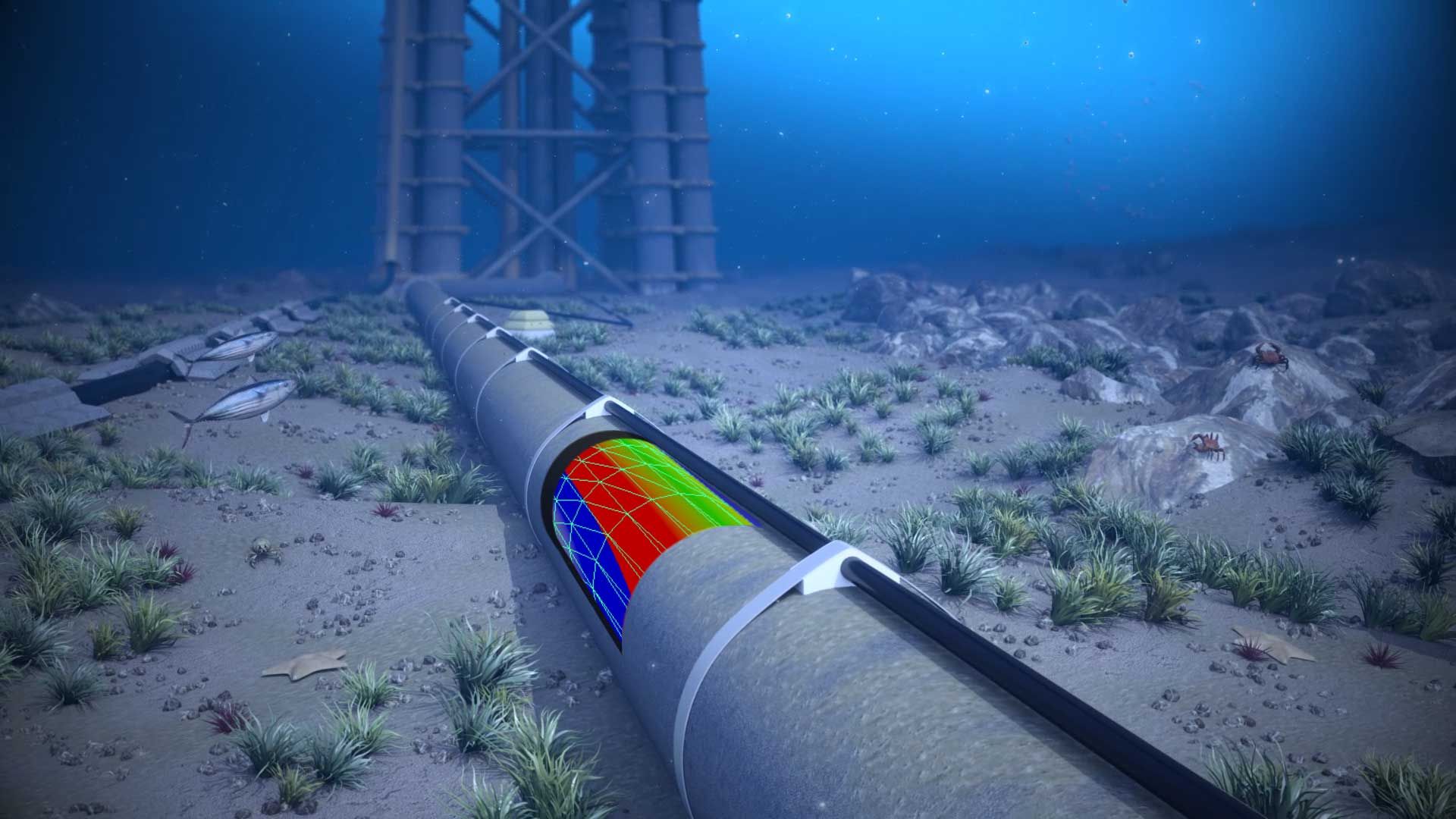

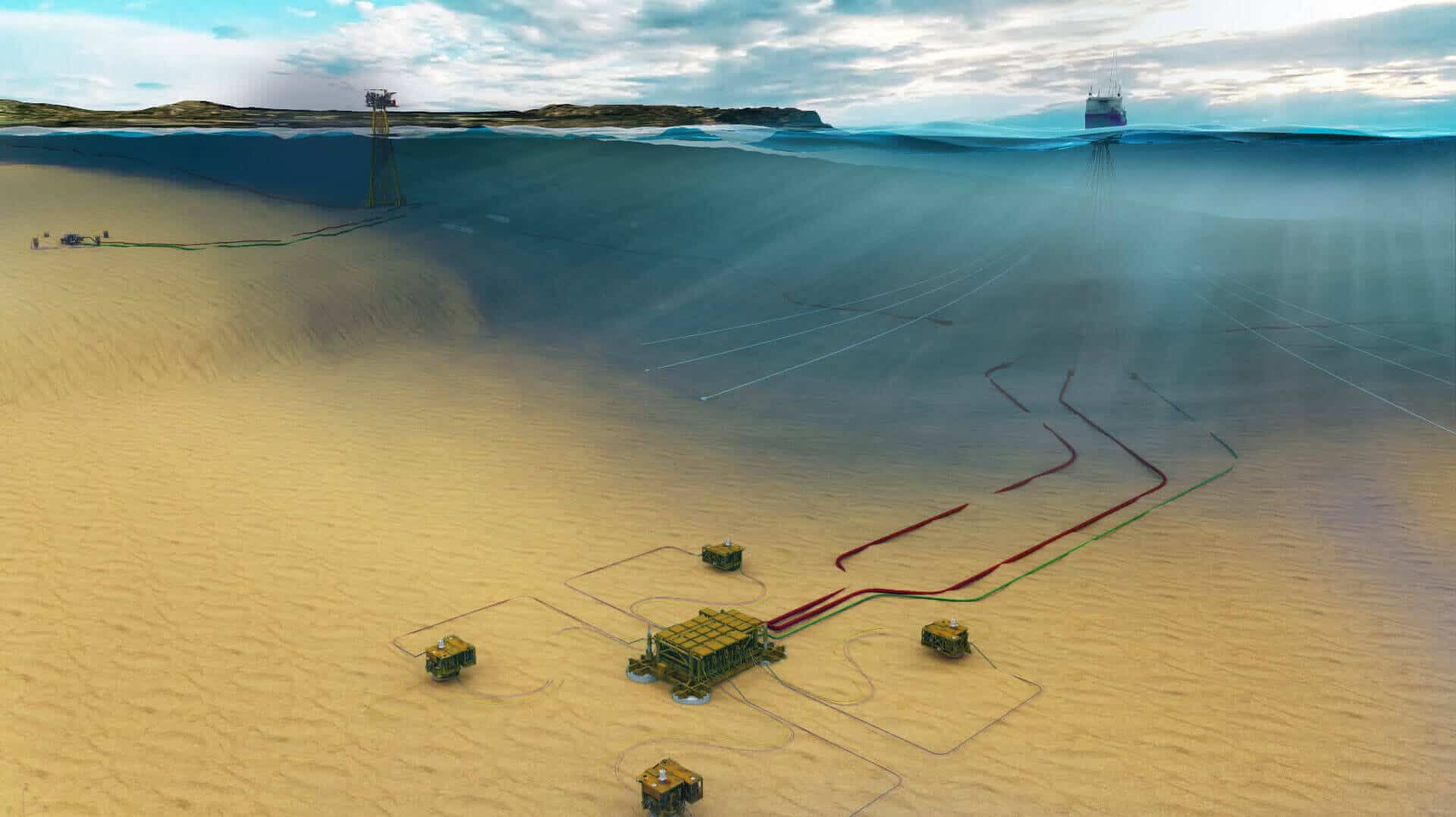

Flow assurance is one of the earliest and most crucial activities to be undertaken in any subsea project. Selection of the optimal line size, hydrate strategy and definition of the myriad operational constraints and requirements is key to maximising overall project value.

Atteris has the expertise and practical experience to address the most complex flow assurance problems at any stage of an asset’s life cycle, be it during concept development, FEED, detailed design, operations or in support of the decommissioning phase. This includes decontamination assessments.

Atteris can assess all Flow Assurance issues including:

- Liquids management / slugging / surging

- Condensation and corrosion

- Hydrate management

- Wax deposition

- Emulsions

- Asphaltene onset / deposition

- Scale deposition

- Sand transport and erosion