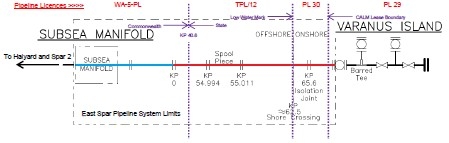

The review performed by Atteris concentrated on compliance with the pipeline license compliance and the original design code. The objective was to assess whether the integrity of the pipeline would be compromised with respect to design for internal pressure.

The review observed that the licensing requirements were at odds with those of the design code. Licensing requirements call for a pressure control facility however AS 2885 (1987) states that an overpressure protection system shall be installed so that the operating pressure does not exceed MAOP by more than 10%. Based on this requirement, Atteris conducted the review looking into the interpretation of terms and definitions in the code and the license, the changes in operating condition, the East Spar pressure source and the required wall thickness methodology.

The review concluded that the pipeline is code compliant, has a pressure control system to ensure pressure is within MAOP and that there is no risk that the MAOP will be exceeded by 10% considering the pressure source. Overpressure scenarios above the MAOP are only possible in an unplanned event such as a SCSSV or PMV failure which is not part of normal operations. Atteris also recommended that a discussion be held with the Regulator with a view to aligning the terminologies, definitions and philosophies in the design code and the regulatory license.