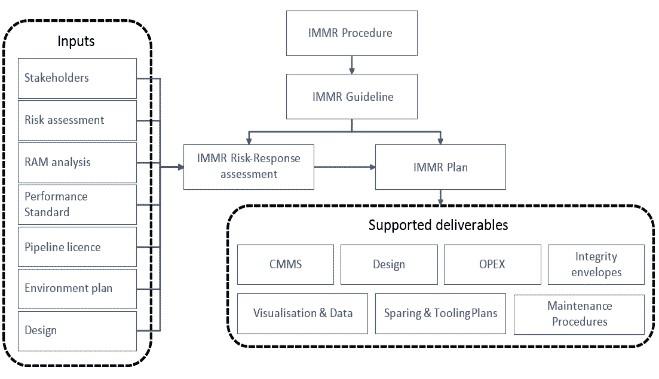

Atteris provided integrity management services for the development of preliminary and final integrity management documentation using a number of different processes. The following documents where developed at the beginning of FEED and at the end of Construction; IMMR Plan, Register of Integrity Threats and IMMR Responses, System Diagrams, RBI Assessment, Operating Envelope, Design Envelope, and Integrity Envelope.

Initially, the systems were split up in accordance with ISO 14224 taxonomic structures. Atteris held workshops with Project Package Engineers identify integrity risks and potential mitigation measures. Monitoring was prescribed as a primary response to reduce unnecessary inspection tasks. Integrity management through the life of the asset leveraged value from the baseline inspection with OPEX being driven by a cost risk analysis. All information was captured in a spreadsheet tool which contained various controls to facilitate easy data manipulation and presentation of results