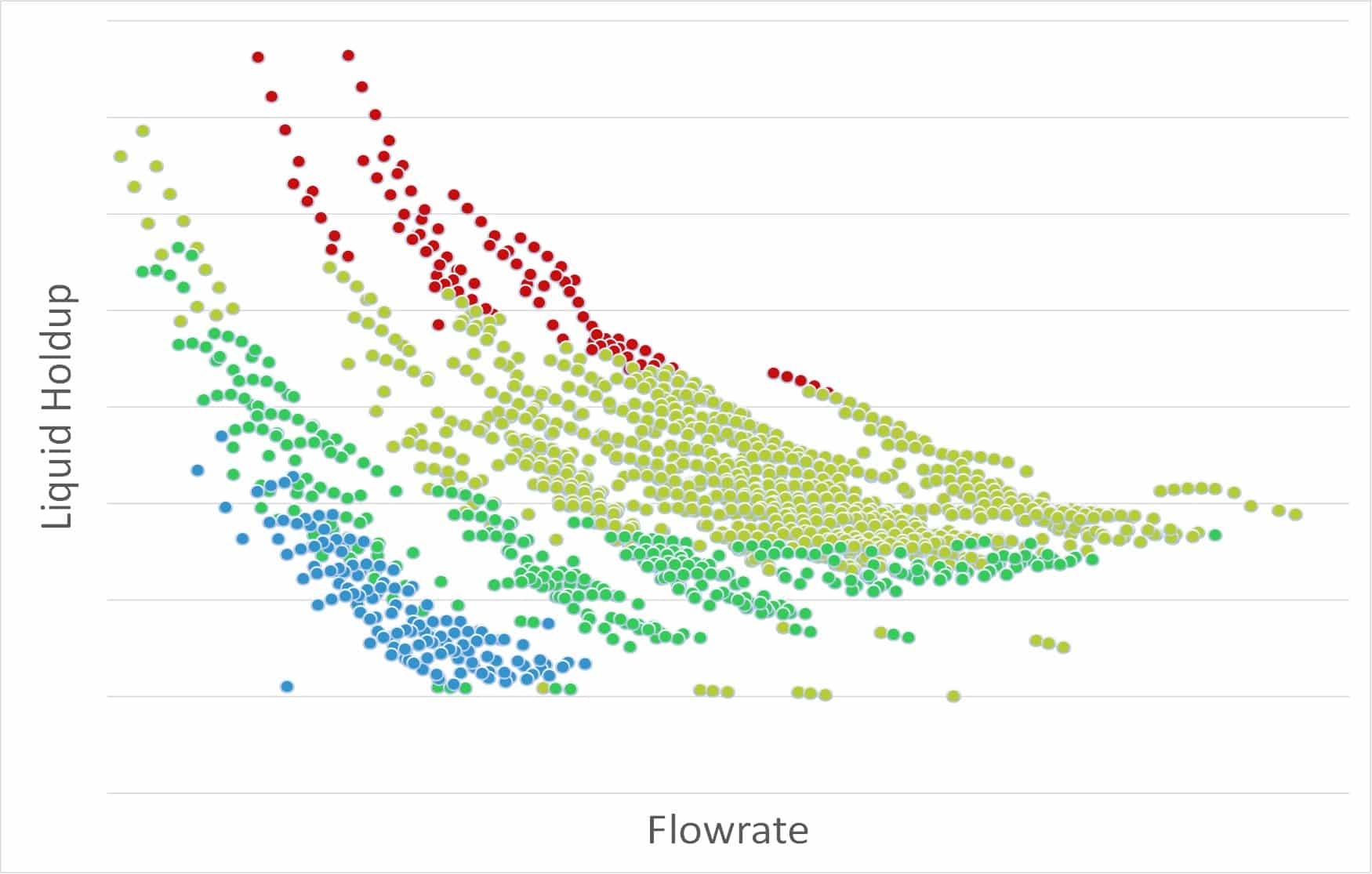

Steady State Parametric Analysis:

Thousands of steady state cases provided key operating data and system insights which were required to finalise the development’s FEED designs. Data from the cases included:

- Operating temperatures and pressures

- Liquid holdup volumes

- Erosional velocity limits, and estimated erosion amounts throughout the system

- Production and gas injection systems’ deliverability curves

- Minimum turndown rates to prevent a range of FA issues

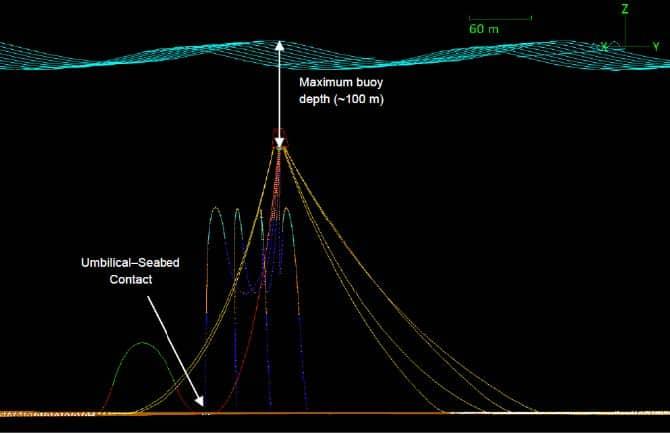

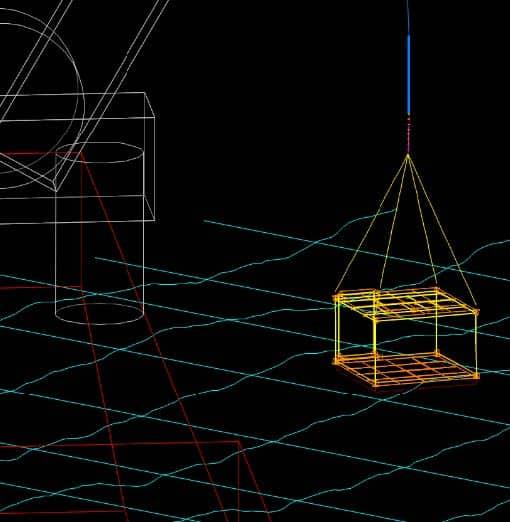

Transient Flow Assurance Analysis:

A large number of transient analyses defined the transient behaviours of the system, including:

- Commissioning and start-up sequences to avoid minimum design temperature exceedances, and to optimise chemical dosing volumes

- Transient liquid surge sequences to define liquid volumes at the FPSO

- Flowline depressurisation sequences to support the Insulate and Blowdown hydrate management strategy (including FPSO restriction orifice sizing to prevent excessive flexible riser depressurisation rates)

- Gas injection system transient cases, defining the behaviour of the near-critical fluids in the gas injection flowline and wells.