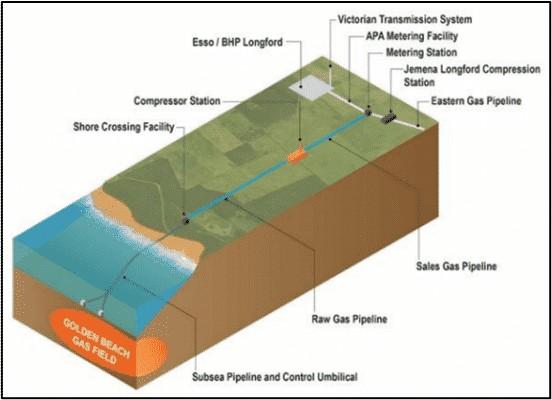

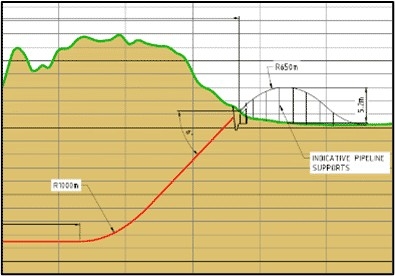

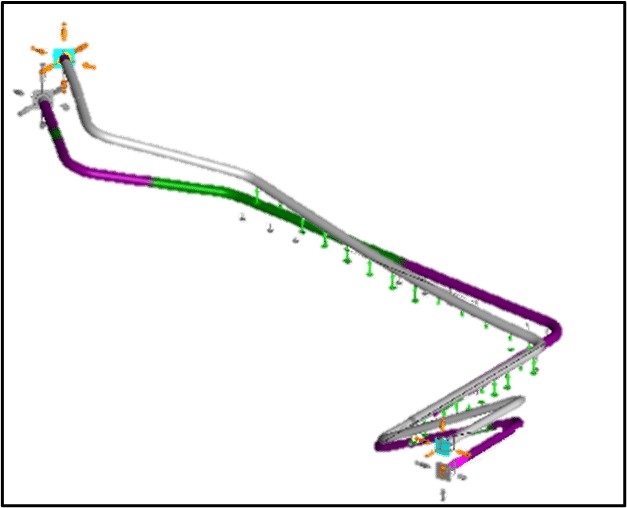

Atteris performed the following activities during FEED:

- Detailed parametric assessment of development concepts, considering installation/operational risk and CAPEX / OPEX estimates various single, dual-pipeline and bundle concepts.

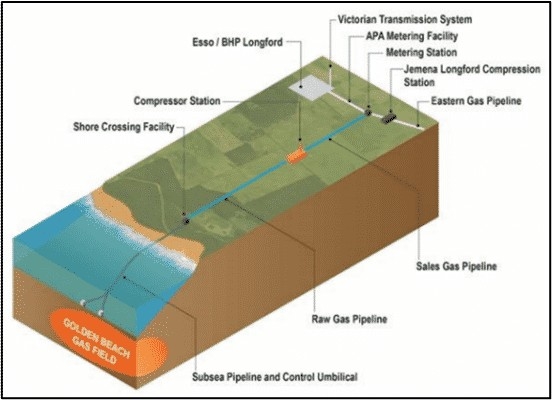

- Shore crossing location selection, site layout and design – evaluating HDD, tunnelling and cut and cover options.

- Pipeline design in accordance with DNVGL-ST-F101 including:

- Pipeline routing optimisation

- Wall thickness selection

- Pipeline stabilisation design

- Cathodic Protection design

- End expansion and buckling susceptibility.

- PLEM definition and field layout definition.

- Tie-in spool design, considering critical operational and installation loading envelopes.

- Flow assurance to define liquid holdup, sand holdup, erosion, hydrate formation and temperature profiles.

- Detailed procurement, operation and IMMR specification, datasheets and documentation development and review.

As an integrated team, Atteris’ broad expertise was leveraged to deliver these wide‑ranging scopes concurrently, efficiently sharing data and knowledge between the internal business streams. This allowed Atteris to deliver an accelerated, cost effective and fit for purpose design that was focussed on ensuring the Client was able identify and mitigate key risks and achieve key contractor engagement schedules.