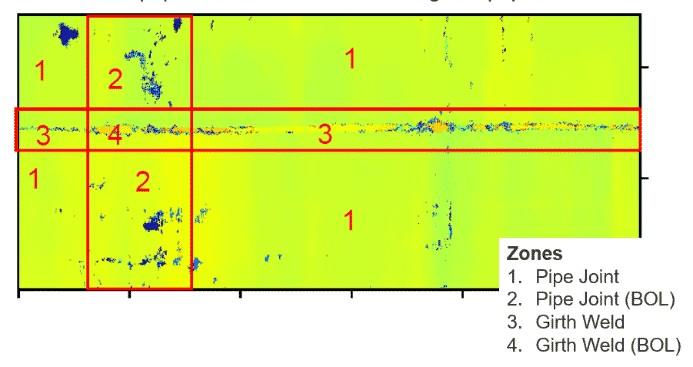

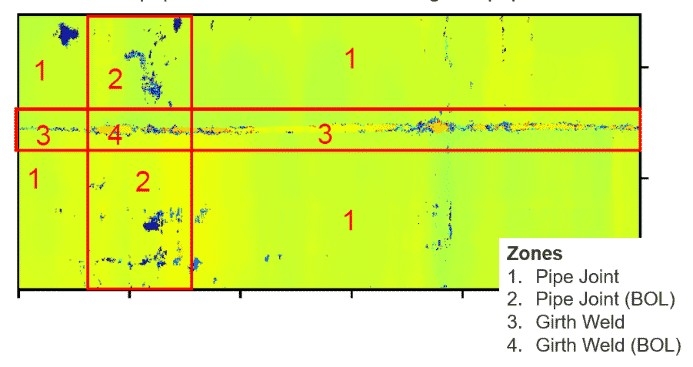

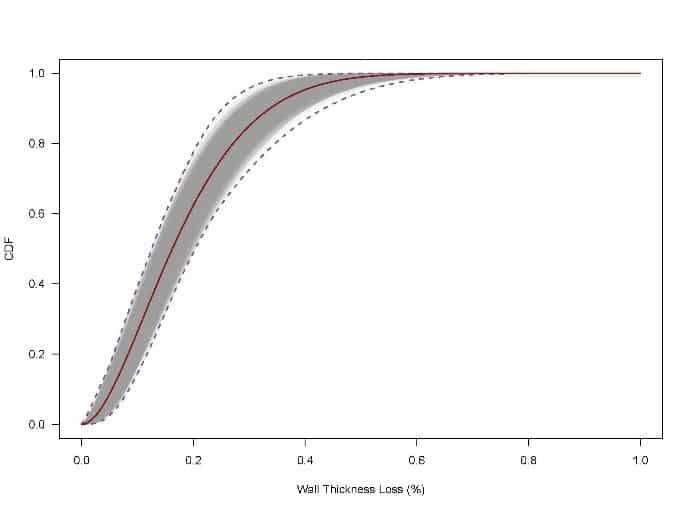

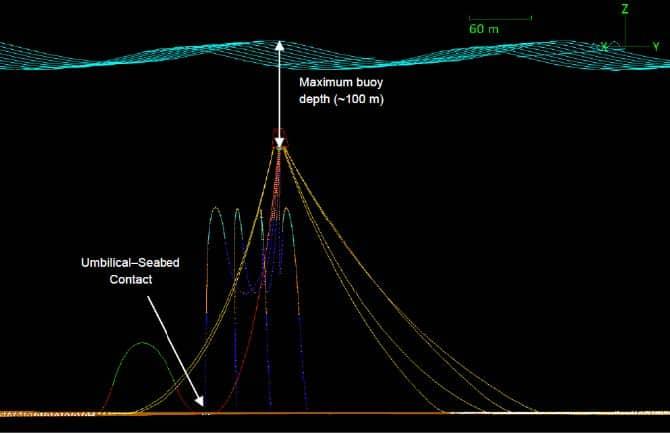

Atteris initially identified all possible corrosion mechanisms and corrosion zones (girth weld, seam weld, top of line, bottom of line, etc.) within the pipeline. Client’s inspection team then inspected a number of girth weld locations at a number of points along the pipeline to obtain a number of datasets for each corrosion zone classification. For each zone classification a statistical assessment was performed. To improve confidence in the cumulative distribution functions (CDFs) a statistical method called “Bootstrapping” was performed for each zone’s CDF. The lower bound confidence interval was then used to determine the likelihood of an unacceptable corrosion feature.

Through this advanced inspection and assessment methodology Atteris were able to give Client a high level of confidence in the corrosion status of the pipeline based on a modest number of spot inspections performed by a vessel of opportunity. This deferred more expensive topsides to subsea in line inspection operation which reduced inspection costs by approximately $15 million (AUD).