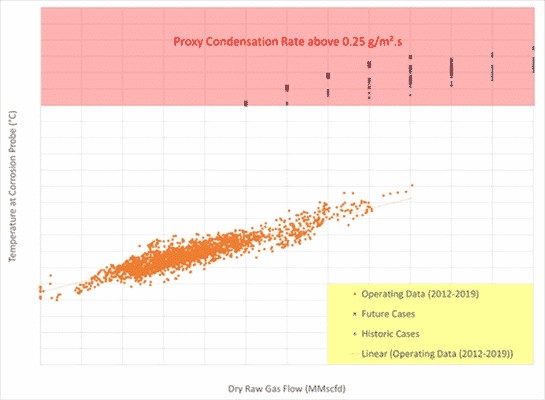

Atteris assessed top of line condensation (TOLC) rates in the Pipeline, particularly at the CRA spool / CS pipeline transition point, for historical and future operations, with the results of this report to be used in subsequent corrosion estimates. The assessment included over 1500 parametric cases to consider all combinations of flowrate, ambient conditions, marine growth and pipeline burial.

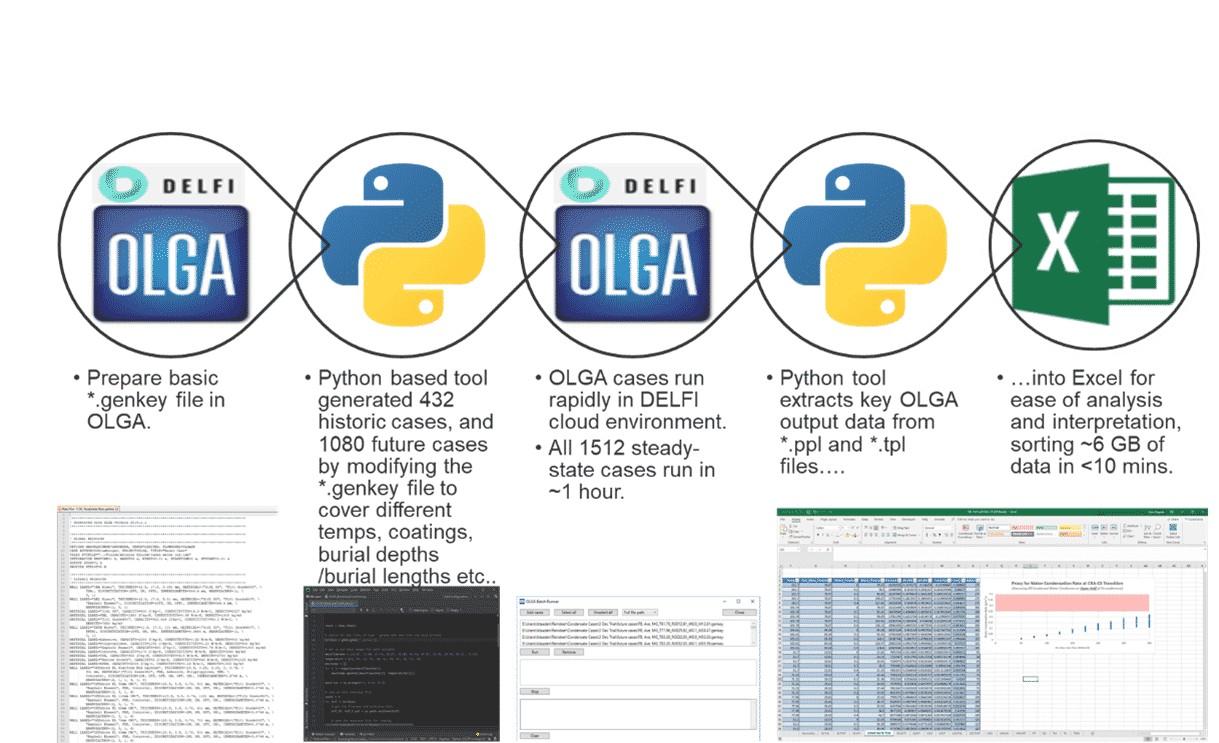

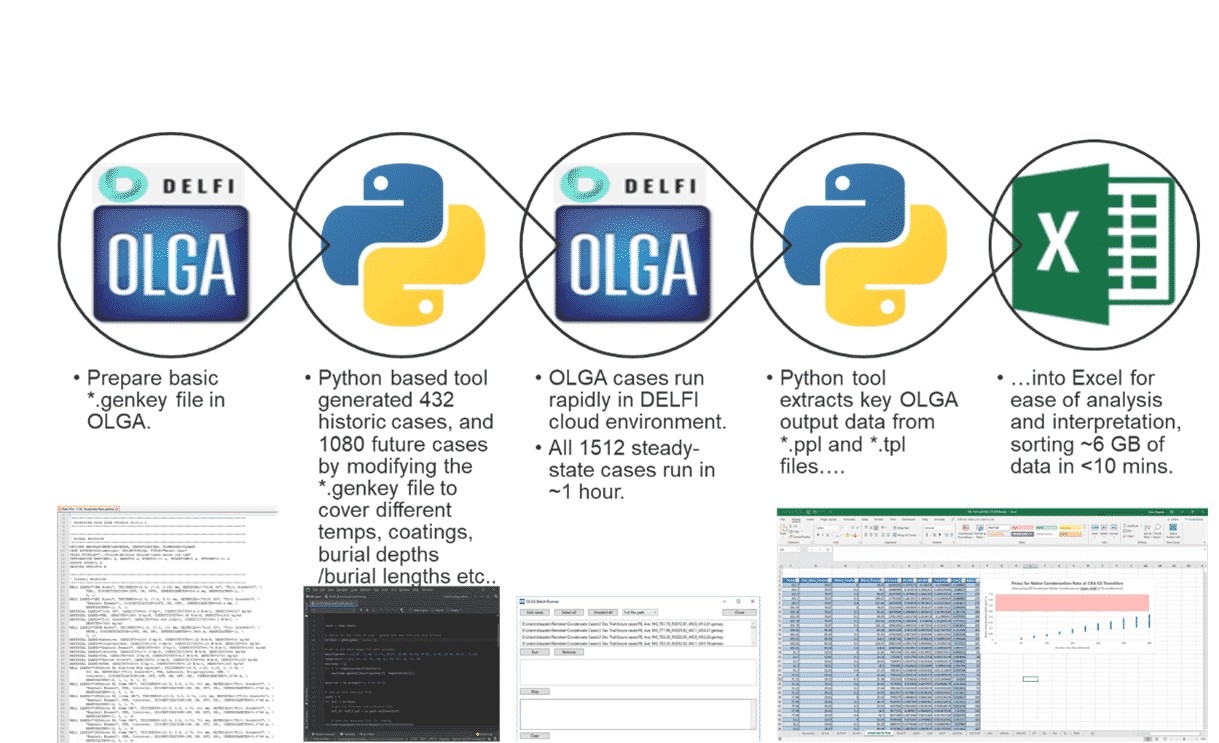

Flow assurance (FA) workscopes historically result in a limited number of OLGA cases in return for a relatively high cost in manhours. For this reason Atteris’ has invested in:

- Automation of our OLGA case preparation. Initially we use the OLGA GUI environment to build a reference model then we use a Python script to produce hundreds or thousands of parametric OLGA cases by modifying the reference model. This is more time-efficient as well as being less prone to human error.

- Faster processing of OLGA cases using OLGA within Schlumberger’s DELFI cloud computing environment. The DELFI cloud computing environment enables OLGA to utilise up to 128 processors to rapidly calculate a given batch of cases. In a recent scope we processed more than 1500 parametric cases of a complex pipeline model in less than an hour. A standard desk-top PC would take an order of magnitude longer to solve this many cases.

- Automation of data extraction from OLGA into EXCEL. We use a Python script to extract bulk OLGA data into EXCEL spreadsheets, allowing client to review OLGA case results in detail without need of the OLGA software. This is more time-efficient as well as being less prone to human error.

This combination of Python scripting / automation and faster OLGA case processing in a cloud computing environment results in Atteris’ steady state parametric flow assurance scopes being cost-competitive relative to much lower manhour rate competitors, whilst also delivering a much larger number of cases with correspondingly better insights into the operation and characteristics of the subject subsea system.

Atteris also used Python scripts to extract all relevant data from all of the steady state and transient cases and import the data into EXCEL. Atteris handed over these EXCEL files to client for its future reference, allowing client to review OLGA case results in detail without need of OLGA software. For each transient case Atteris also provided *.AVI profile graph animations so client could visualise what was happening through the transient event.