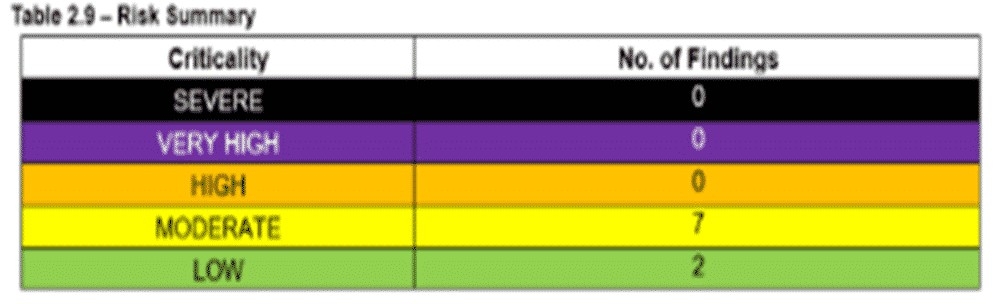

Atteris conducted an update of the RBI assessments for six assets to ensure that the current level of risk is defined, and an adequate inspection interval is assigned to monitor the risks.

The RBI assessment was based on data received from monthly reports, inspection reports, design documents, engineering studies and management of change records. A timeline of events which had an impact on asset integrity was also prepared.

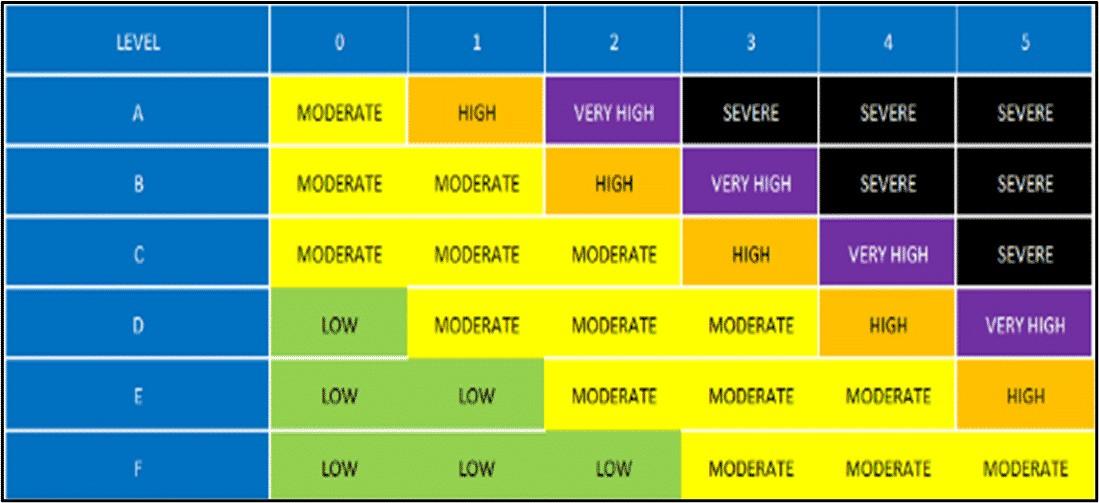

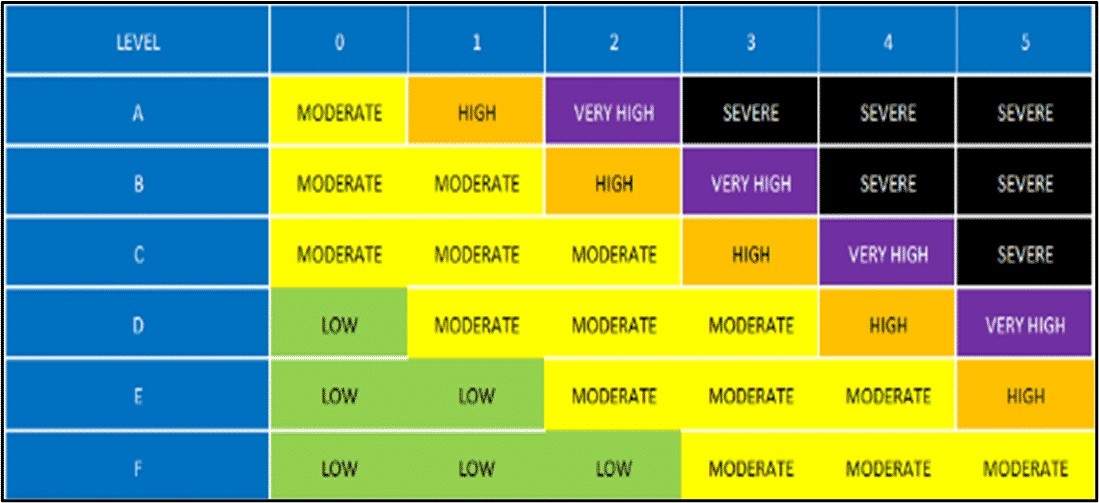

For each asset damage loop, Atteris defined the credible degradation mechanisms and determined the likelihood and consequence of failure based on data that was available. Confidence levels in the inspection technique was taking into consideration.

Workshops were held with the Client, during which the results of the RBI assessment were presented and discussed.

Individual RBI reports for each asset were prepared. The reports contained a high-level summary of the recommended inspection techniques and intervals.